Profitec Pro 300: Fill Solenoid Inspection and ServiceUpdated 5 months ago

Tools Needed:

- 14mm crescent wrench

- Adjustable wrench

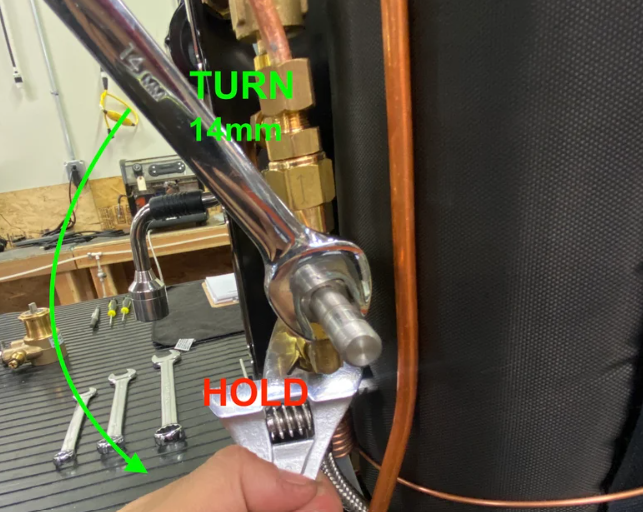

- #2 Philips screw driver

- Scotch-Brite pad

1) First, you will need to drain the boilers, then unplug the machine and allow it to cool.

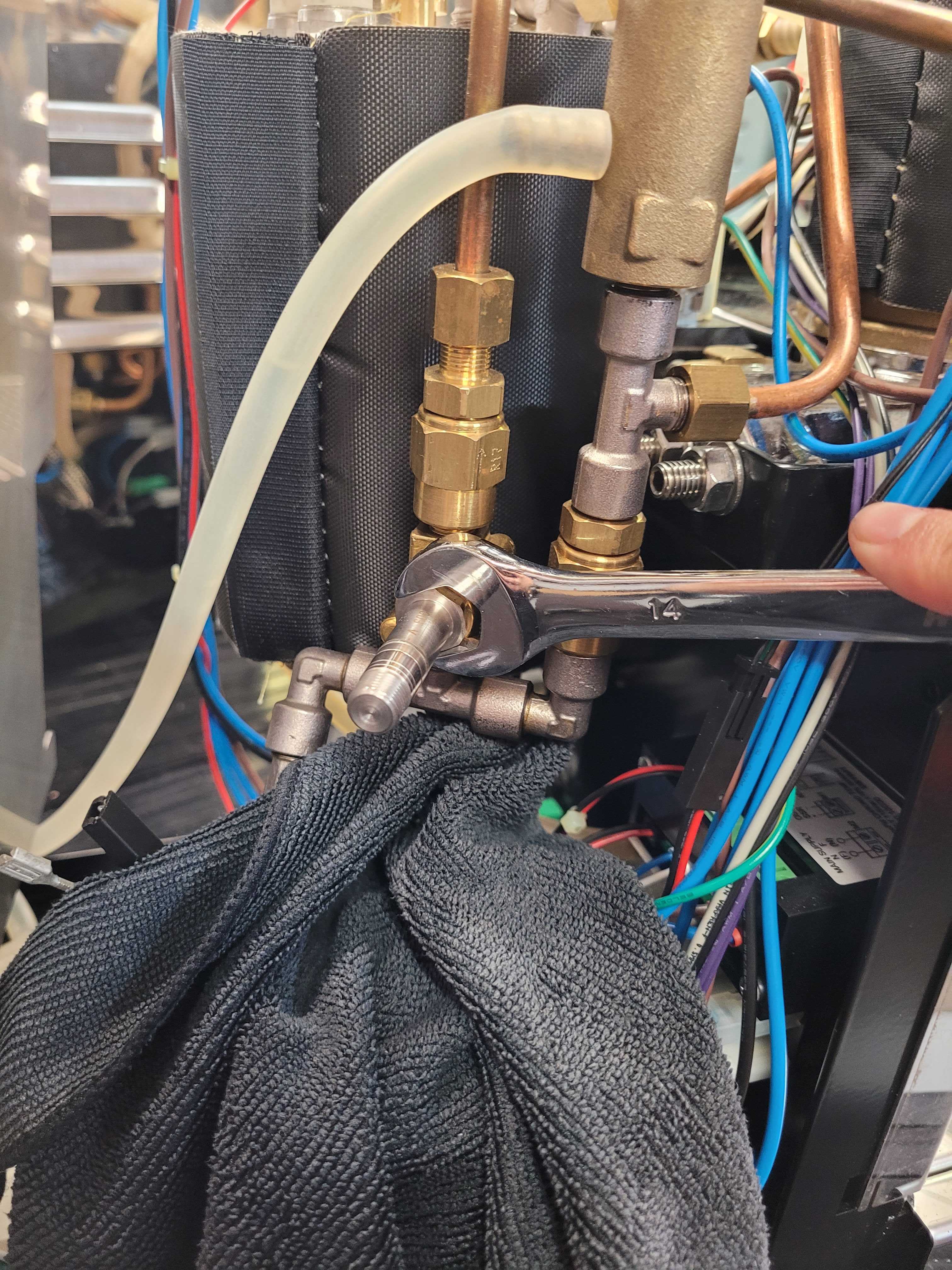

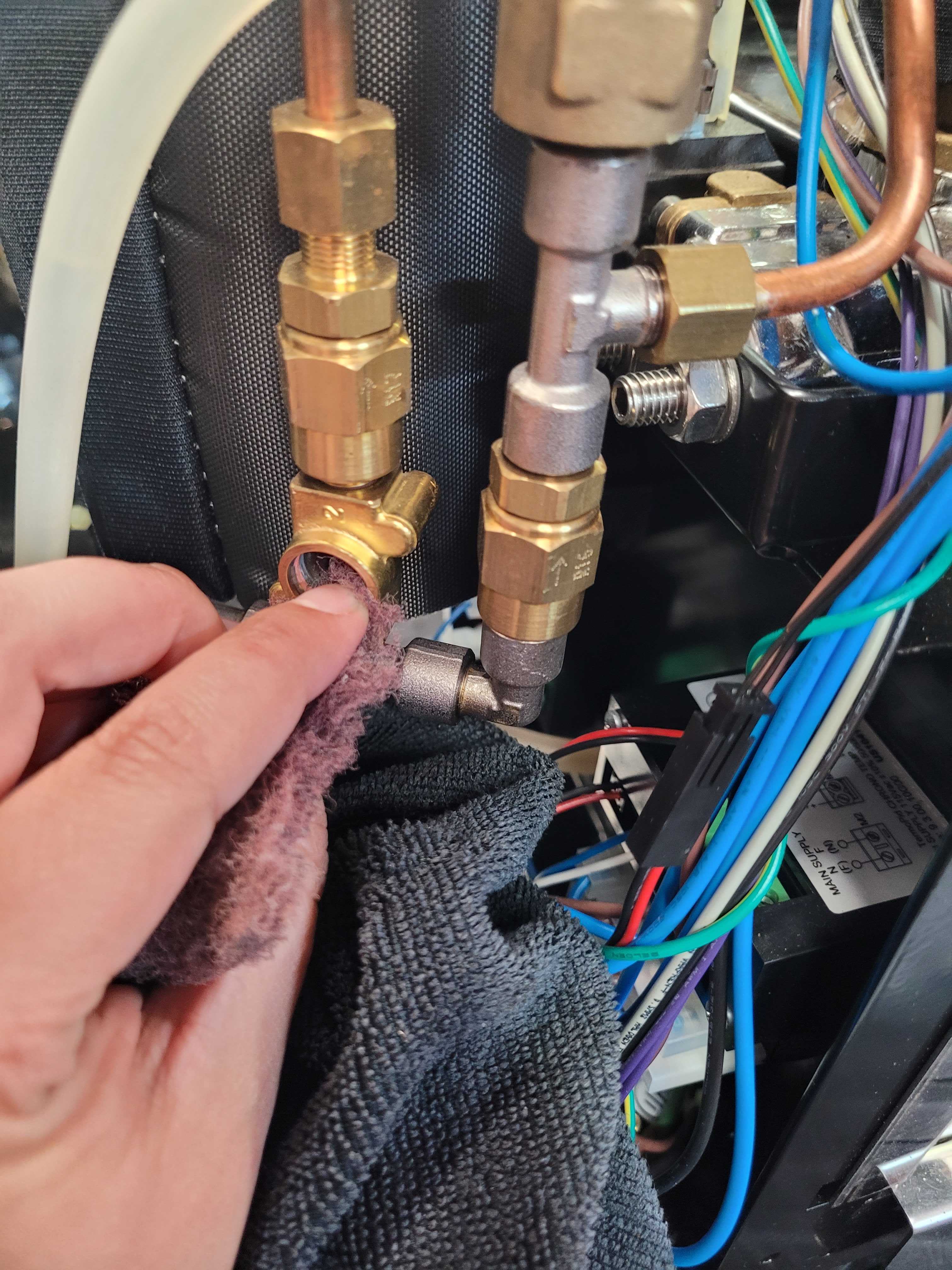

2) Remove the panels from the machine. You will also want to remove the reservoir holder to gain access to the solenoid.

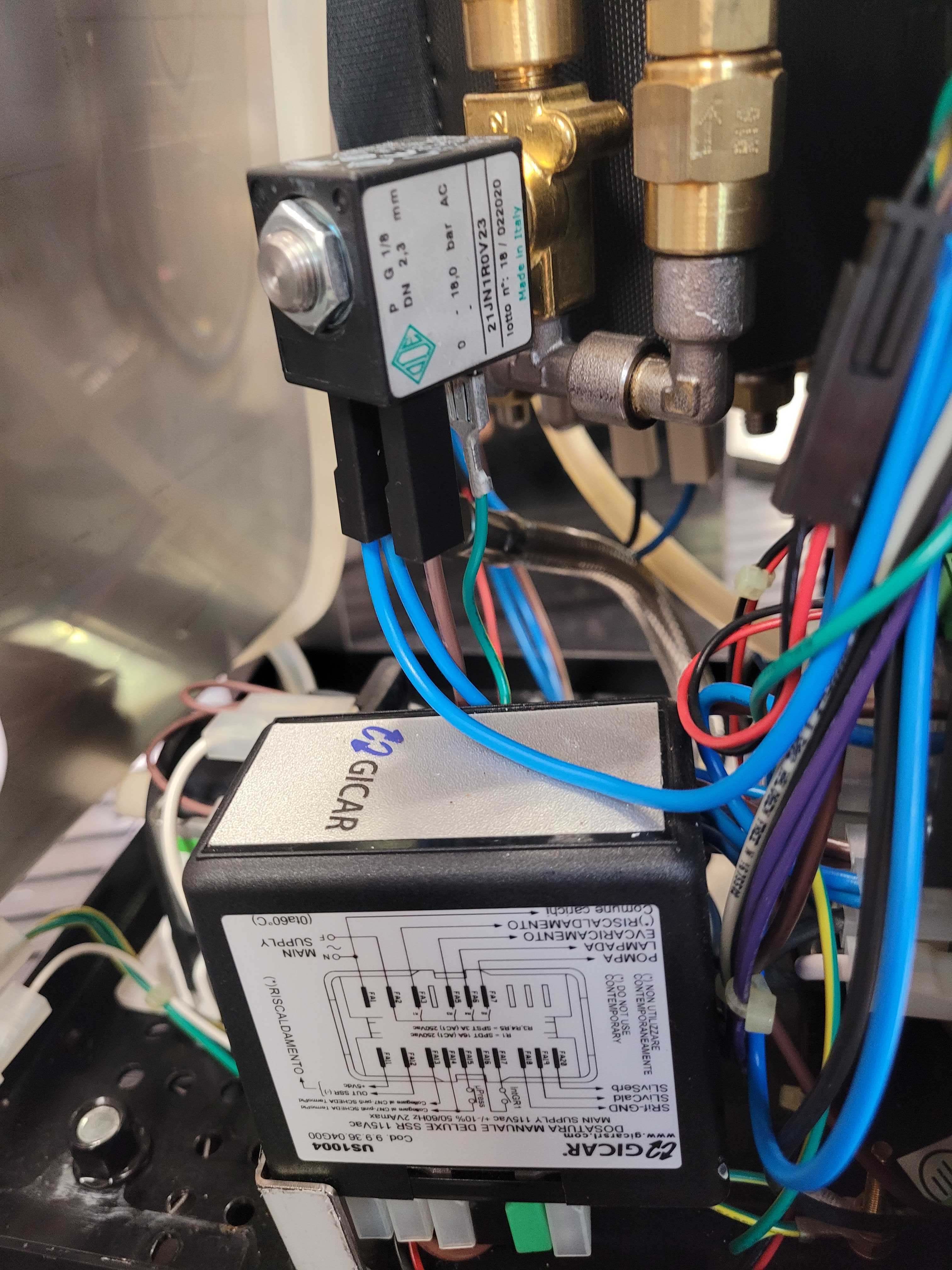

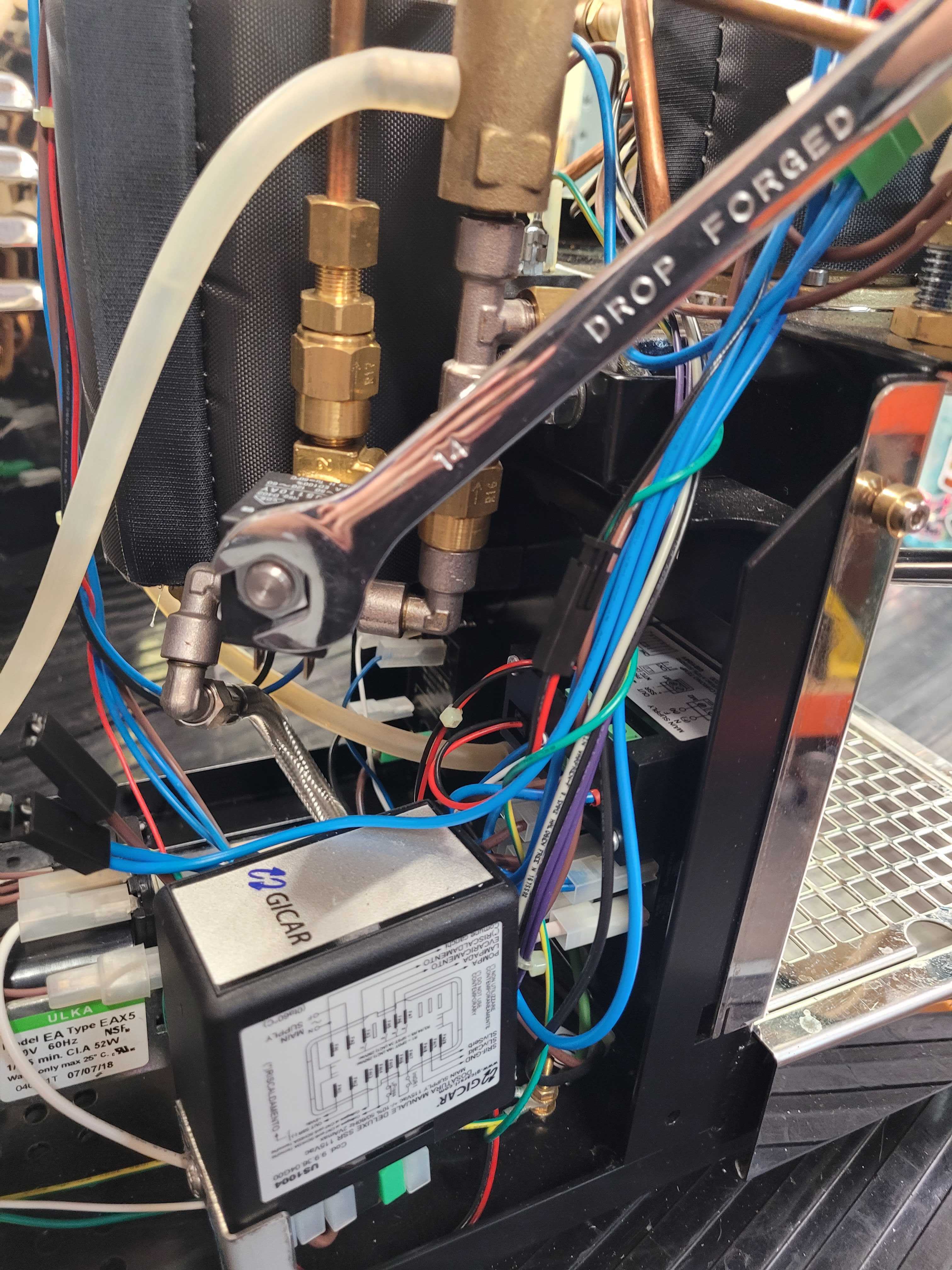

3) Identify the fill solenoid.

4) Use the 14mm wrench to unscrew the solenoid retaining nut from the solenoid box.

5) Slide the solenoid box off of the armature.

7) Unscrew the armature from the brass valve body. Be sure to use a second wrench to hold the valve body steady while you turn the armature. (There may be a bit of water that comes out, so you might want to place a towel over the electronic components)

8) Inspect and clean the inside of the armature and make sure that the gasket looks clean and the spring is able to move freely.

9) Don't forget to clean the inside of the valve body.

10) Reassemble the fill solenoid by following these steps in reverse, replacing any parts that need service.