Bezzera Duo MN: Expansion Valve (OPV) Adjustment and ServiceUpdated 5 months ago

Tools Needed:

- 3mm Allen key or hex driver

- Adjustable wrench

- 16mm open-ended wrench

- Needle nose pliers

- Pick

- Wire bristle brush or scouring pad

NOTE: If your machine is being used plumbed-in to a water supply line, you must have a pressure regulator on the line to limit the inlet pressure at the machine to 30-40 PSI. High inlet pressure can cause premature wear to the expansion valve and damage the machine's internal components.

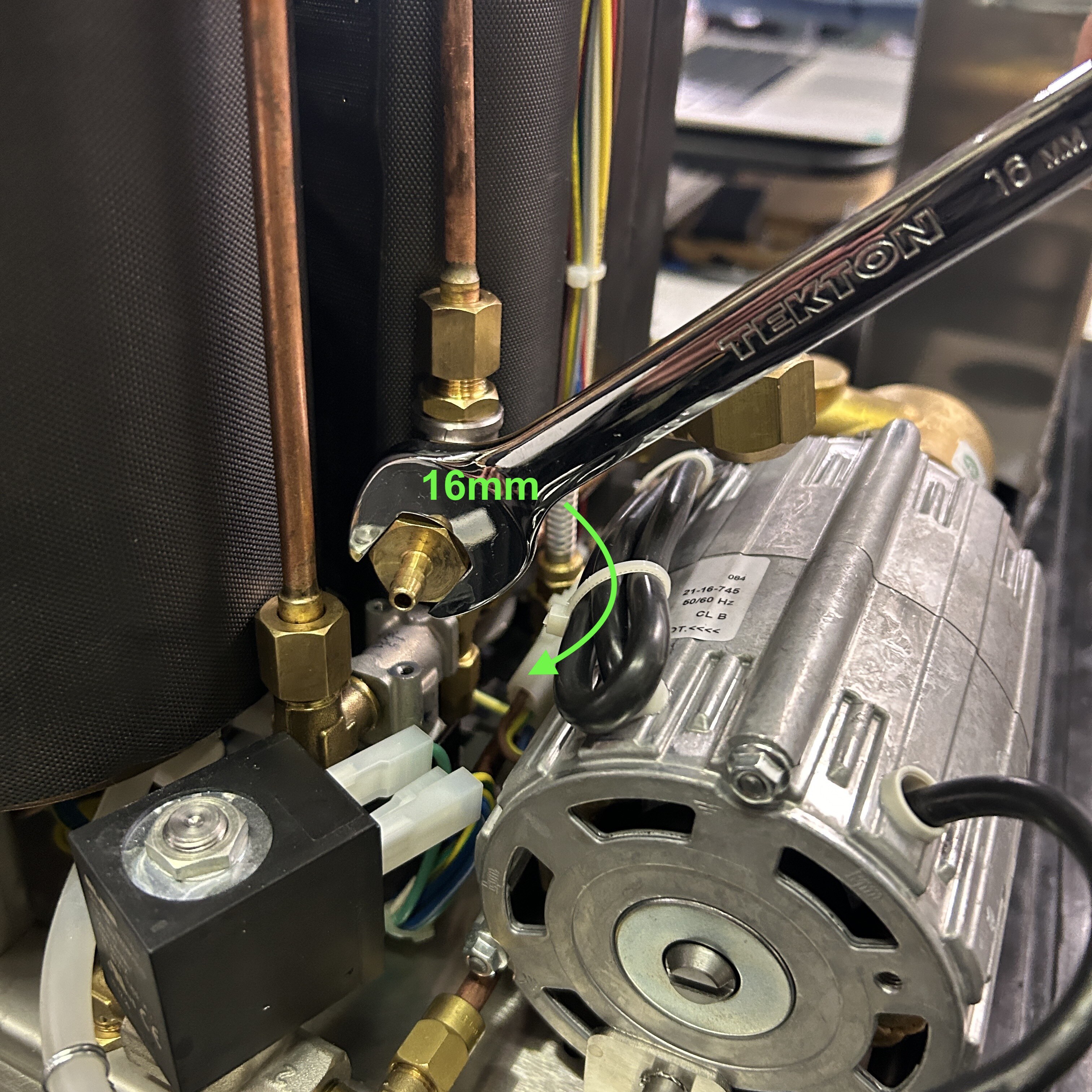

1. Remove the panels from the machine.

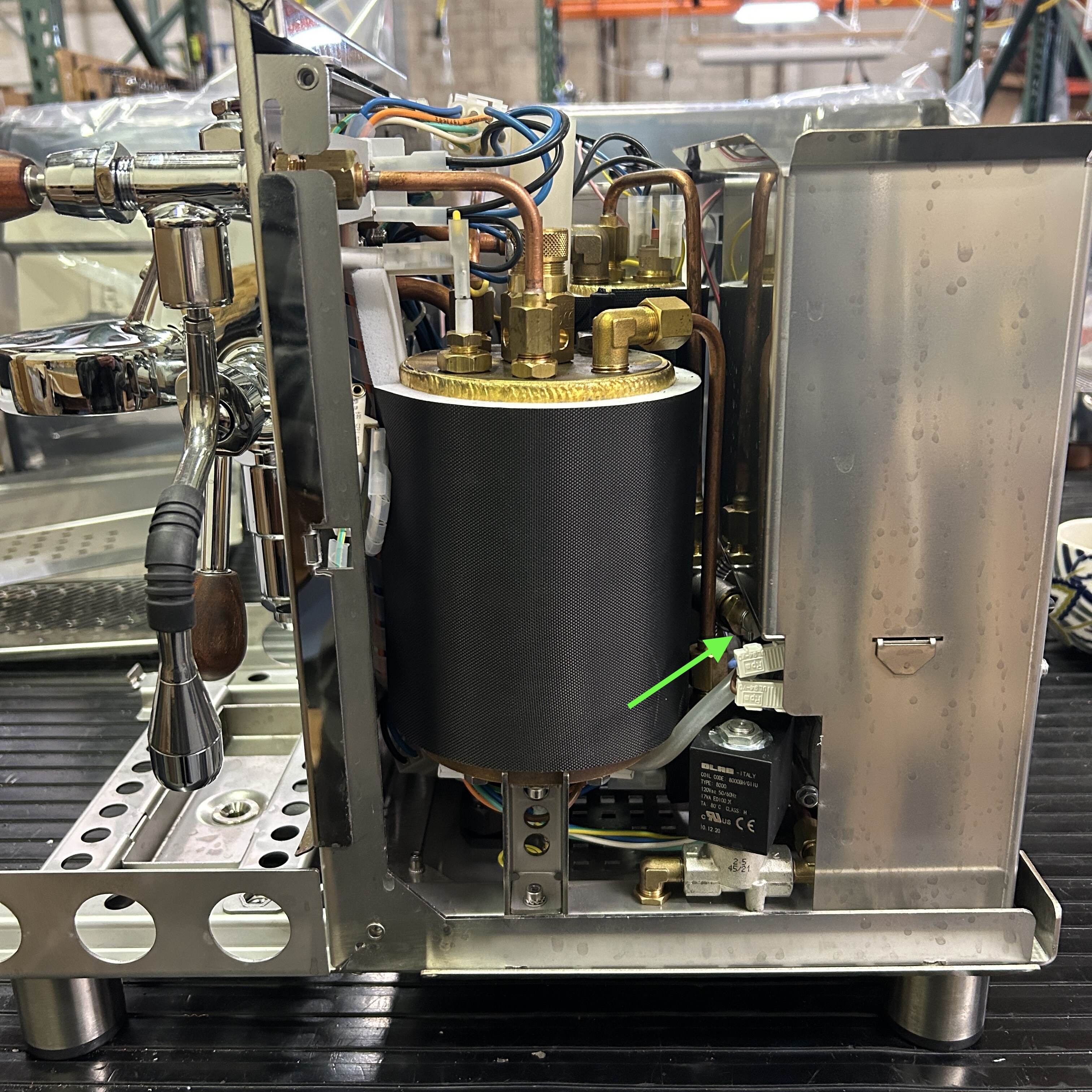

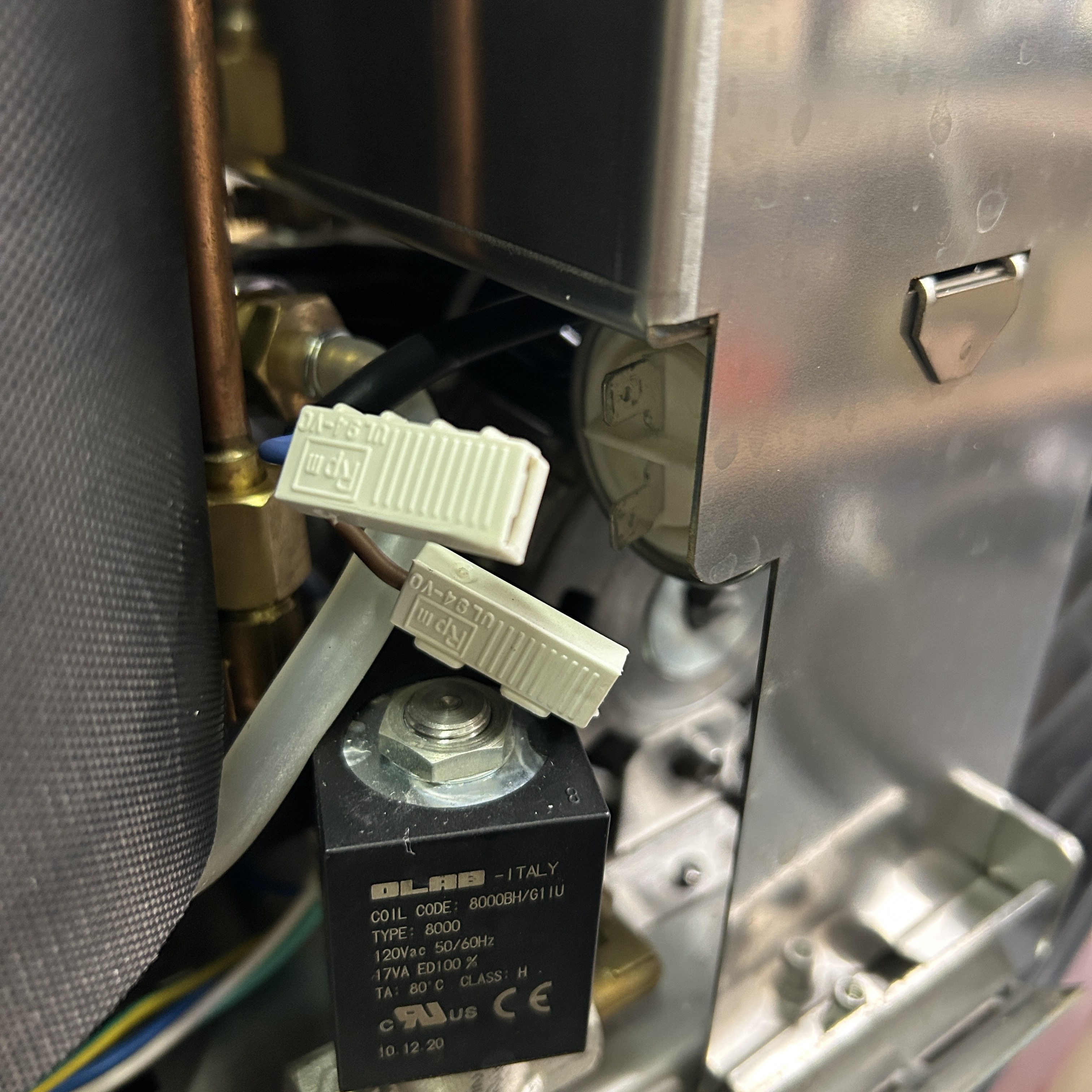

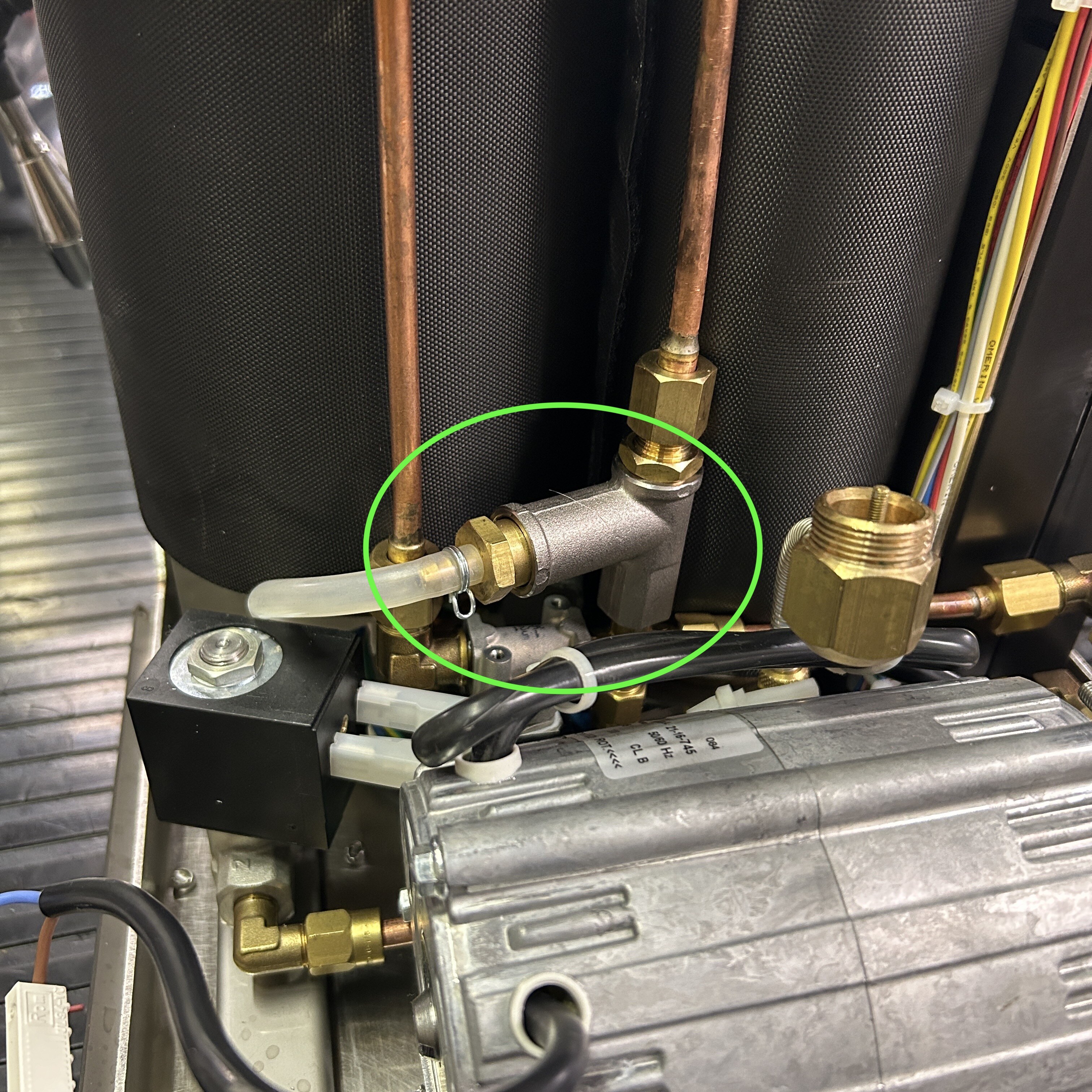

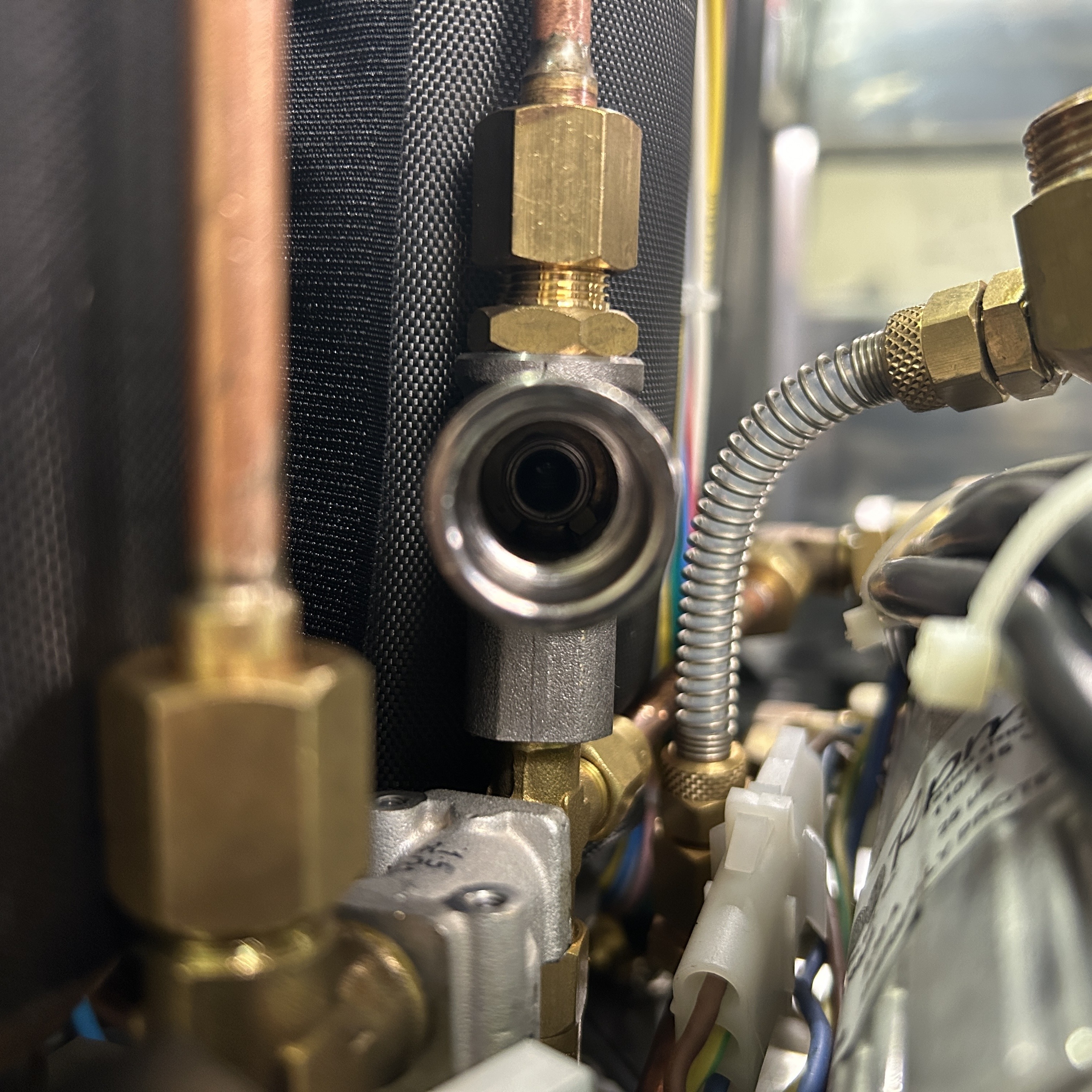

2. Identify the expansion valve inside the machine.

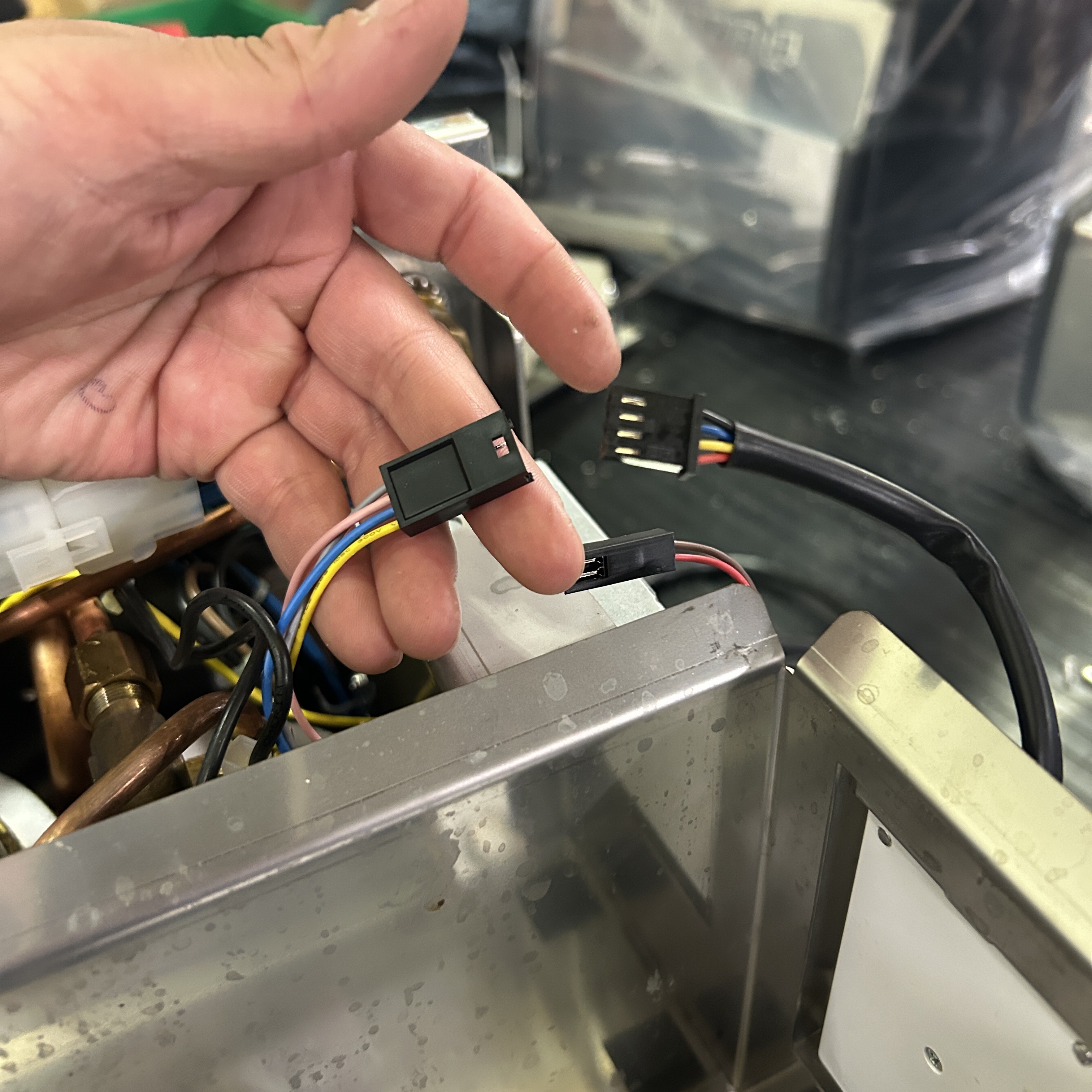

3. To access the expansion valve, we'll need to remove the reservoir tray. Start by unplugging the following electrical connections:

4. Use the adjustable wrench to unscrew the reservoir inlet; be careful not to lose this big nut.

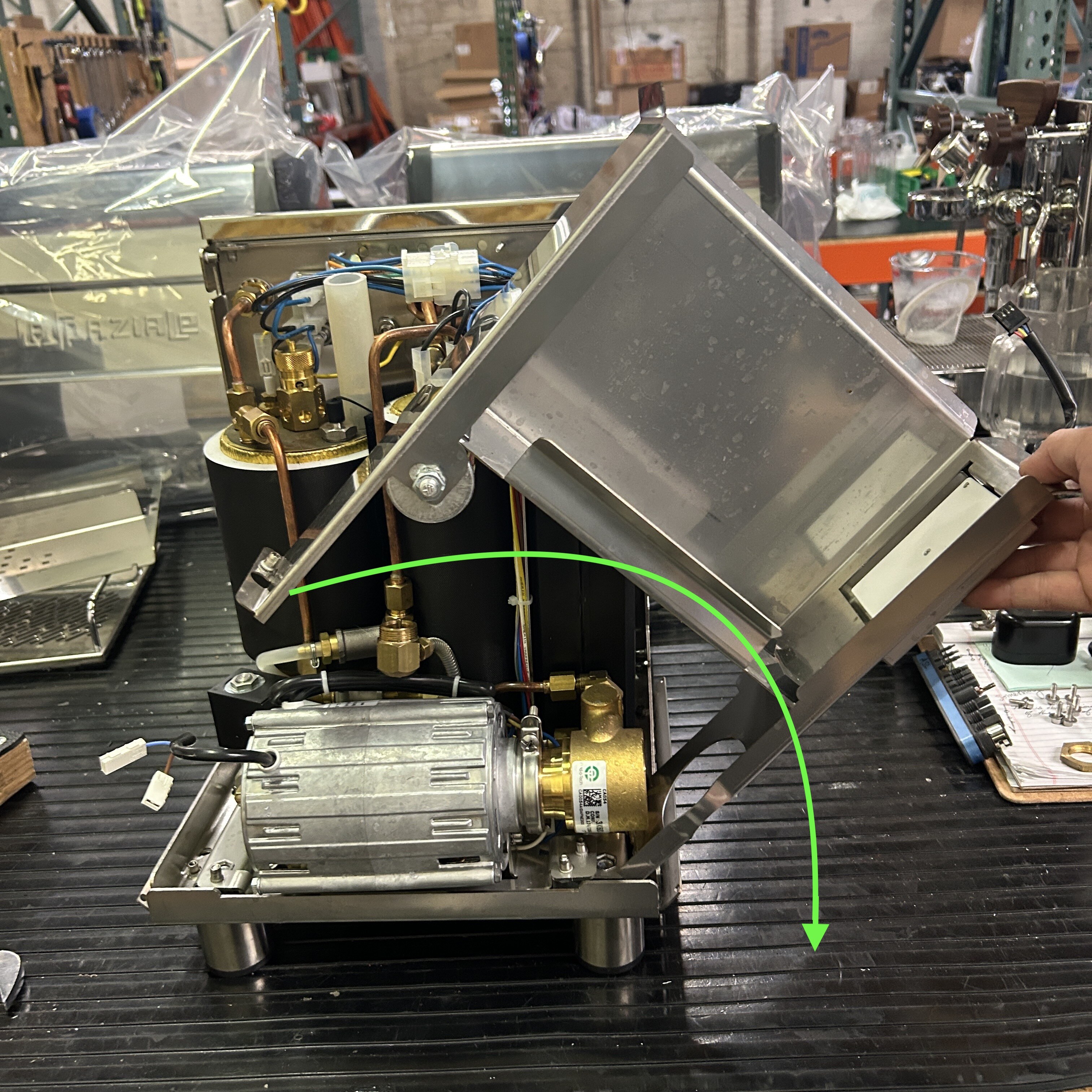

5. Tilt the machine forward to access the underside, then use the 3mm Allen key to unscrew the reservoir tray mounting screws.

6. Rotate the now-free reservoir tray 90º onto the side closest to the machine's pump, then pull straight up to remove the reservoir tray from the machine. Set the tray aside.

7. You now have full access to the expansion valve.

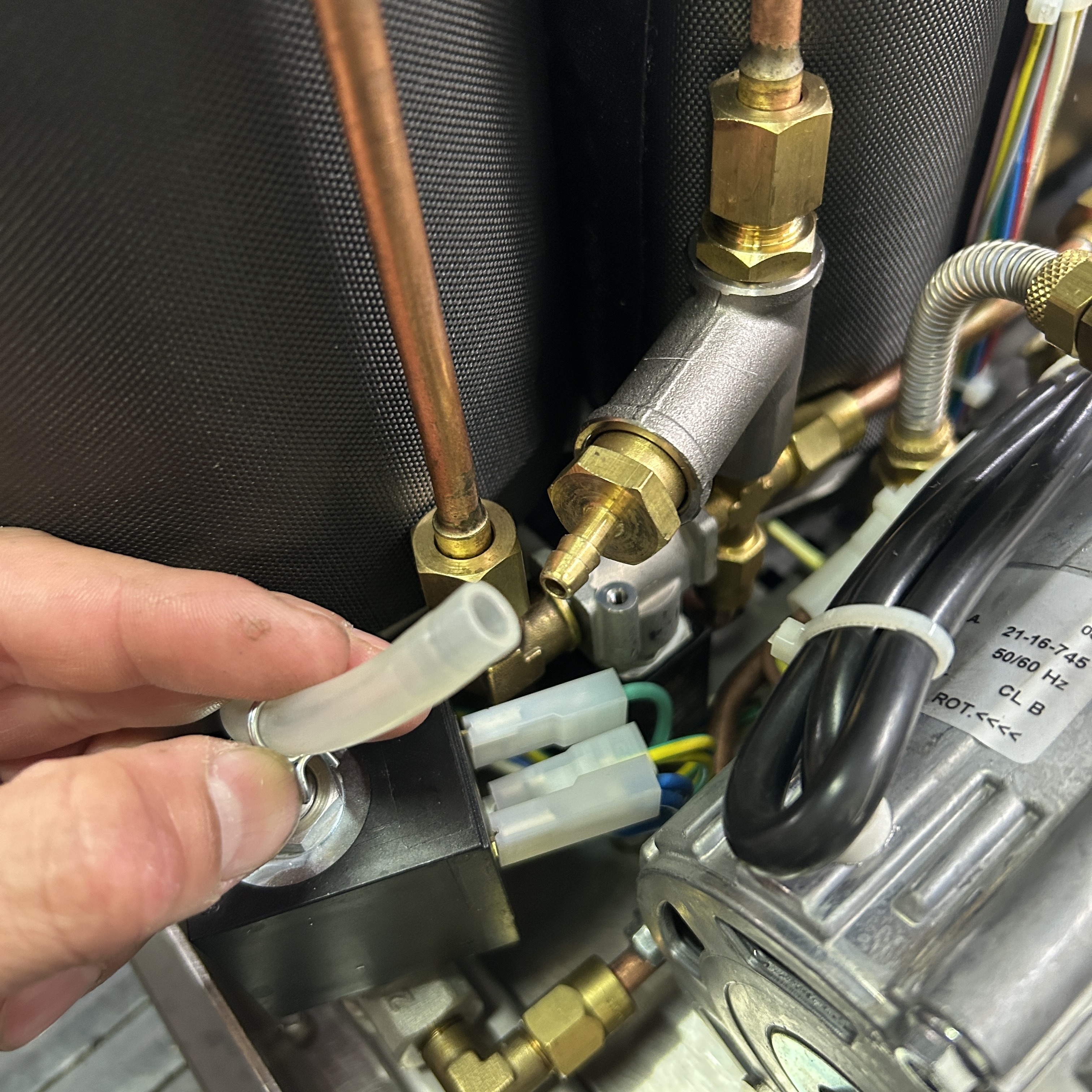

8. Remove the silicone tube from the expansion valve outlet; a pair of pliers will help you compress the retaining clamp.

9. Start by adjusting the expansion valve. Turn the adjustment cap 1-2 full turns clockwise, then replace the drain tube and reinstall the reservoir tray to test the machine. Repeat until the expansion valve stops leaking.

If no amount of adjustment resolves the leak, the expansion valve will need to be serviced.

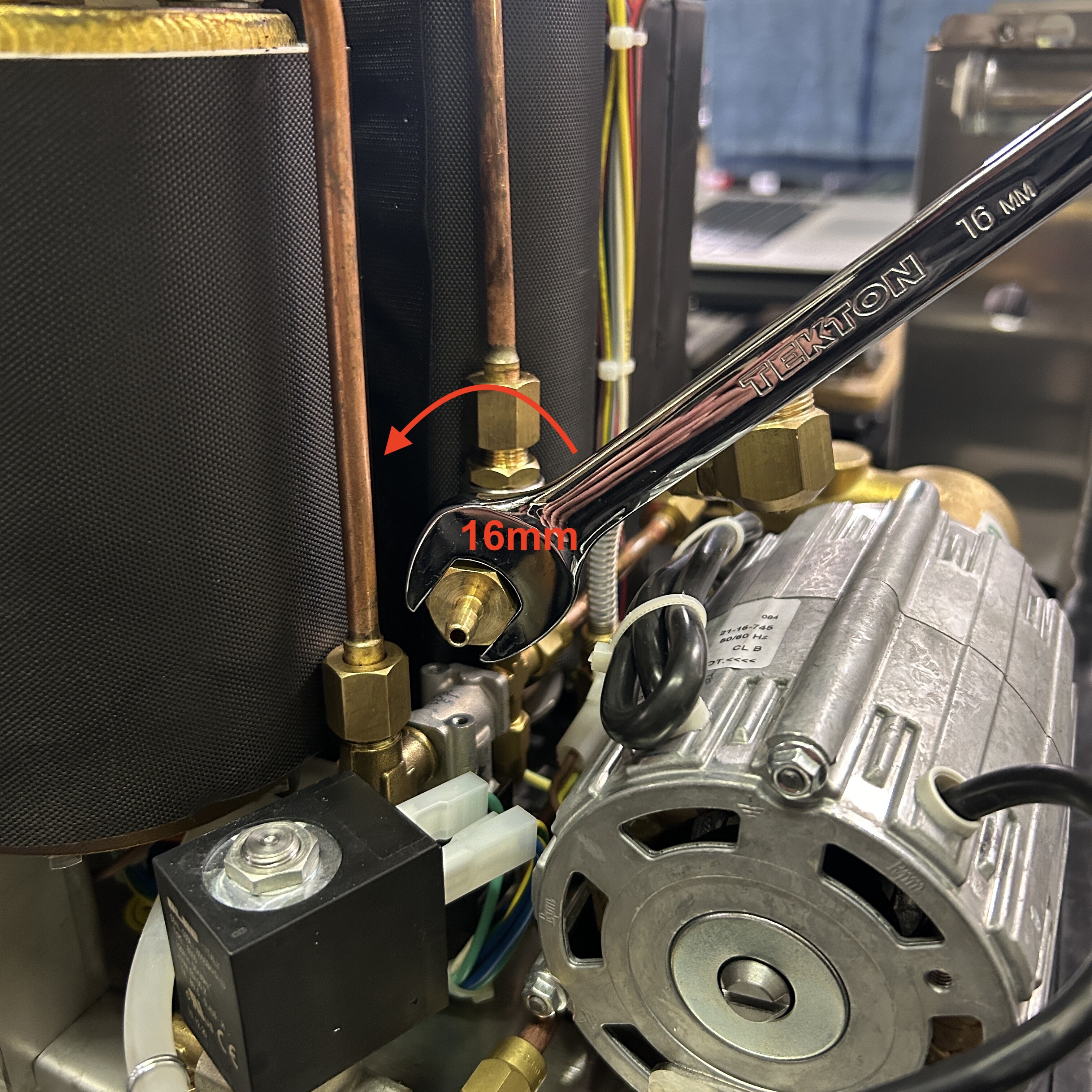

10. Fully unscrew the expansion valve adjustment cap by turning it counter-clockwise until it separates from the expansion valve body. Take note of the orientation of the internal components.

11. Clean any build up from the expansion valve components using a wire bristled brush or scouring pad.

12. Don't forget to inspect and clean inside the valve body.

13. Inspect the rubber expansion valve seat for excess wear, damage, or build up. Replace the expansion valve seat if necessary—in a pinch, the expansion valve seat can be flipped around and reused.

14. Reassemble the expansion valve components in the proper order and screw the adjustment cap back into the expansion valve body. Screw the adjustment cap in all the way to seat the valve seat, then back the adjustment cap out 1-2 full turns. Replace the drain tube and reinstall the reservoir tray to test the machine.